Your The technique for joining copper water pipes is called images are ready in this website. The technique for joining copper water pipes is called are a topic that is being searched for and liked by netizens now. You can Download the The technique for joining copper water pipes is called files here. Get all free vectors.

If you’re searching for the technique for joining copper water pipes is called images information related to the the technique for joining copper water pipes is called keyword, you have pay a visit to the right blog. Our website frequently gives you hints for refferencing the maximum quality video and image content, please kindly surf and locate more informative video articles and graphics that match your interests.

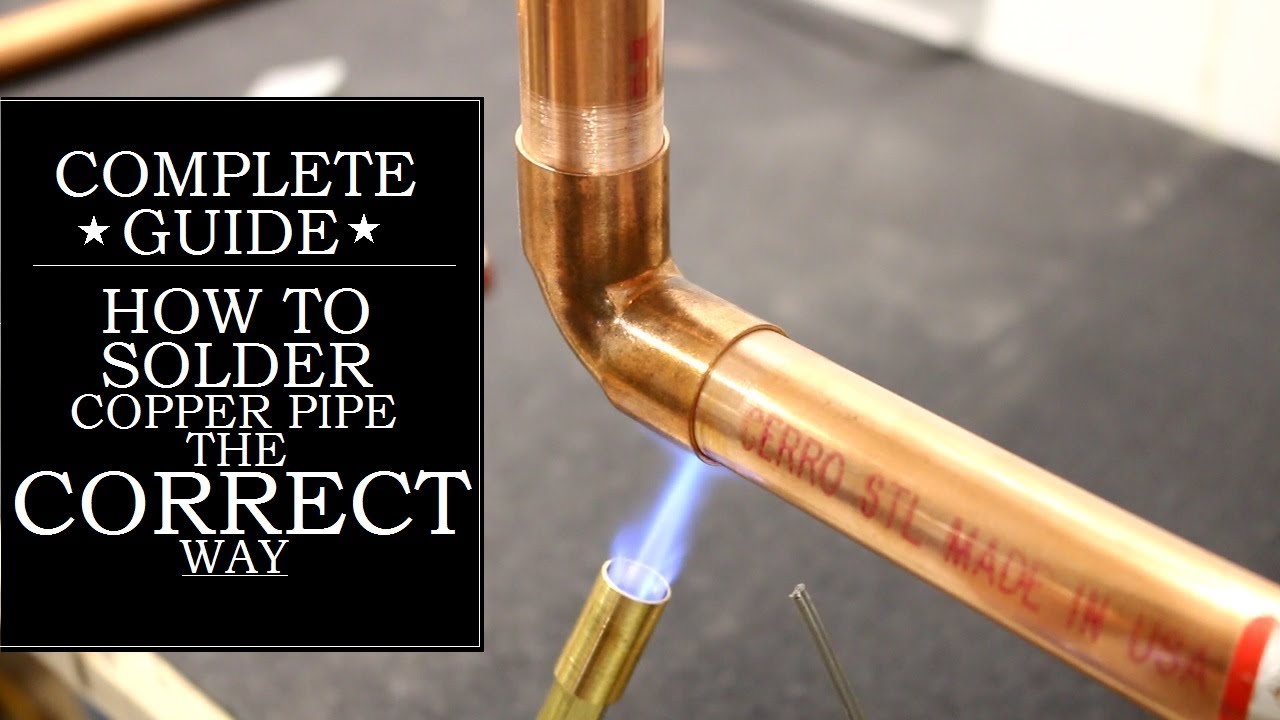

The Technique For Joining Copper Water Pipes Is Called. The basic process for joining brass or copper pipes is essentially the same. Click for details Solvent Weld Solvent welding also known as solvent cementing or solvent bonding is the process of joining. Also known as a silver solder brazed joints are used to join plain-end copper or copper-alloy pipe with solder end-type fittings. Solder the brass half to the copper pipe thread the steel half onto the galvanized steel pipe with Teflon tape then join the two together tightly with the joining nut.

Pin On Basteln Diverse Themen From pinterest.com

Pin On Basteln Diverse Themen From pinterest.com

Soft soldering normally uses Tin based solders for joining copper and b ras s when high mechanical strength is not required. It is called this way because the process involves first heating a joint between two copper pipes and then allowing flux material to melt and fill the joint or seam. Hard copper tubing is most difficult to flare and is expressly not meant for that purpose. Clean the pipe ends that you intend to join until they are shiny and free from any burrs or debris. A compression fitting consists of three parts. A small addition of phosphorus at 00150040 is added to remove oxygen from the copper.

An easy and fast way to connect PVC to the copper pipe without welding or to glue is using push-fit fittings.

It also is used to join aluminum piping with special filler metals. Ball-and-spigot and mechanical joints have cast iron plumbing pipes and fittings for water mains. It also is used to join aluminum piping with special filler metals. It is important to note that the melting point of the parent material pipe material should be higher than the filler material. It is joined using a soldersweat roll grooved compression or crimpedpressed connection. These joining methods include soldering brazing and electric resistance.

Source: instructables.com

Source: instructables.com

Copper pipes with a tee joint. The basic process for joining brass or copper pipes is essentially the same. Its far easier to make a repair to steel pipe with copper than with galvanized plumbing pipe because the galvanized calls for cutting threads on exact lengths of pipe. At one time replacing water supply pipes usually meant installing new copper pipes joined with sweat-soldered fittings that required a flame torch and considerable skill to assemble. Soft soldering normally uses Tin based solders for joining copper and b ras s when high mechanical strength is not required.

Source: youtube.com

Source: youtube.com

This small addition of phosphorous reduces the electrical and thermal conductivity to about 85 of pure copper. The other type of pipe joint is found in plastic pipes where. Brazed joints have less mechanical strength. Soldering is used on all three plumbing systems water waste and vent piping. Flexed joint for copper water pipe.

This is nearly pure at 999 min Copper content. Solder or Brazed Joints. Soft soldering normally uses Tin based solders for joining copper and b ras s when high mechanical strength is not required. Its far easier to make a repair to steel pipe with copper than with galvanized plumbing pipe because the galvanized calls for cutting threads on exact lengths of pipe. Clean the pipe ends that you intend to join until they are shiny and free from any burrs or debris.

Source: balkanplumbing.com

Source: balkanplumbing.com

Soldering is used on all three plumbing systems water waste and vent piping. Next brush on the plumbing flux and push the pipes together. Click for details SV Gasket The SV gasket joining method is most often used with cast iron soil pipe. Copper water pipe in the USA is designated as copper alloy C12200. Mechanical joints are metal rings that are bolted into place and fitted rubber sealing.

Source: pinterest.com

Source: pinterest.com

Compression fittings are a way of joining copper pipes or a copper pipe to a fixture where you cant solder or where you may have to take the joint apart in the future. These joining methods include soldering brazing and electric resistance. When galvanized pipe comes into play the male and female ends of pipe are threaded together to form a bond. Soldering is used on all three plumbing systems water waste and vent piping. At one time replacing water supply pipes usually meant installing new copper pipes joined with sweat-soldered fittings that required a flame torch and considerable skill to assemble.

Source: oneprojectcloser.com

Source: oneprojectcloser.com

Solder or Brazed Joints. Also known as a silver solder brazed joints are used to join plain-end copper or copper-alloy pipe with solder end-type fittings. Ball-and-spigot and mechanical joints have cast iron plumbing pipes and fittings for water mains. It also is used to join aluminum piping with special filler metals. Soft soldering normally uses Tin based solders for joining copper and b ras s when high mechanical strength is not required.

Source: pinterest.com

Source: pinterest.com

Clean the pipe ends that you intend to join until they are shiny and free from any burrs or debris. Ball-and-spigot and mechanical joints have cast iron plumbing pipes and fittings for water mains. In plumbing this technique is mostly done with copper piping. It is joined using a soldersweat roll grooved compression or crimpedpressed connection. Solder the brass half to the copper pipe thread the steel half onto the galvanized steel pipe with Teflon tape then join the two together tightly with the joining nut.

Source: pinterest.com

Source: pinterest.com

Click for details Solvent Weld Solvent welding also known as solvent cementing or solvent bonding is the process of joining. When galvanized pipe comes into play the male and female ends of pipe are threaded together to form a bond. Brazing is done for connecting copper pipes or copper alloy pipes. Using Push-fit Fittings. Solder or Brazed Joints.

Source: homedepot.com

Source: homedepot.com

An easy and fast way to connect PVC to the copper pipe without welding or to glue is using push-fit fittings. These joining methods include soldering brazing and electric resistance. It is called this way because the process involves first heating a joint between two copper pipes and then allowing flux material to melt and fill the joint or seam. Solder or Brazed Joints. Brazing is done for connecting copper pipes or copper alloy pipes.

Source: instructables.com

Source: instructables.com

Click for details Solvent Weld Solvent welding also known as solvent cementing or solvent bonding is the process of joining. A small addition of phosphorus at 00150040 is added to remove oxygen from the copper. To be locked in place tightly the pipe is just pushed into the fitting to get it watertight sealed. Ball-and-spigot and mechanical joints have cast iron plumbing pipes and fittings for water mains. Rigid or Hard copper tubing is generally referred to as pipe.

Source: balkanplumbing.com

Source: balkanplumbing.com

Brazed joints with capillary fittings are used where greater joint strength is required or where service temperatures are. Toilet supply line is a good example. A compression fitting consists of three parts. Type L and M copper are meant to be soldered or brazed to join lengths of it together as they are considered hard copper tubing. A compression type fitting used for flared copper is called a flare fitting.

Source: deq.utah.gov

Source: deq.utah.gov

It is important to note that the melting point of the parent material pipe material should be higher than the filler material. Rigid or Hard copper tubing is generally referred to as pipe. Hard copper tubing is most difficult to flare and is expressly not meant for that purpose. Copper piping is referred to by nominal pipe size or the inner diameter. Its far easier to make a repair to steel pipe with copper than with galvanized plumbing pipe because the galvanized calls for cutting threads on exact lengths of pipe.

Source: pinterest.com

Source: pinterest.com

Finally heat up the fitting using a torch while dripping liquid solder into the joint to create a secure and water-tight barrier. Besides for copper it is also commonly used for other metal pipes. In plumbing this technique is mostly done with copper piping. This is nearly pure at 999 min Copper content. These joining methods include soldering brazing and electric resistance.

Source: theplumbinginfo.com

Source: theplumbinginfo.com

There are several categories of methods to join copper tube and fittings. Flexed joint for copper water pipe. A compression nut a compression ring or ferrulea metal or plastic washer that will be compressed against the fitting and the compression. Pipe Joining Methods Soldered This is the process of joining pipe by melting a filler metal with a low melting point into a joint. The basic process for joining brass or copper pipes is essentially the same.

Source: quora.com

Source: quora.com

Copper water pipe in the USA is designated as copper alloy C12200. Toilet supply line is a good example. Type L and M copper are meant to be soldered or brazed to join lengths of it together as they are considered hard copper tubing. Copper was the plumbing pipe of choice from the 1950s until 2000 and was widely used both in new construction and to replace the galvanized steel water supply pipes that had been the standard into the 1950s. Click for details SV Gasket The SV gasket joining method is most often used with cast iron soil pipe.

Source: diynetwork.com

Source: diynetwork.com

A compression nut a compression ring or ferrulea metal or plastic washer that will be compressed against the fitting and the compression. To be locked in place tightly the pipe is just pushed into the fitting to get it watertight sealed. This is nearly pure at 999 min Copper content. Finally heat up the fitting using a torch while dripping liquid solder into the joint to create a secure and water-tight barrier. Copper water pipe in the USA is designated as copper alloy C12200.

Source: youtube.com

Source: youtube.com

Toilet supply line is a good example. Also known as a silver solder brazed joints are used to join plain-end copper or copper-alloy pipe with solder end-type fittings. The other type of pipe joint is found in plastic pipes where. A compression fitting consists of three parts. Using Push-fit Fittings.

Source: homedepot.com

Source: homedepot.com

Flexed joint for copper water pipe. Copper pipes with a tee joint. Toilet supply line is a good example. A small addition of phosphorus at 00150040 is added to remove oxygen from the copper. Rigid copper is a popular choice for water lines.

This site is an open community for users to submit their favorite wallpapers on the internet, all images or pictures in this website are for personal wallpaper use only, it is stricly prohibited to use this wallpaper for commercial purposes, if you are the author and find this image is shared without your permission, please kindly raise a DMCA report to Us.

If you find this site helpful, please support us by sharing this posts to your own social media accounts like Facebook, Instagram and so on or you can also save this blog page with the title the technique for joining copper water pipes is called by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.