Your This drive pulley always turns images are available. This drive pulley always turns are a topic that is being searched for and liked by netizens today. You can Find and Download the This drive pulley always turns files here. Find and Download all free vectors.

If you’re looking for this drive pulley always turns pictures information related to the this drive pulley always turns interest, you have pay a visit to the ideal blog. Our website frequently gives you hints for downloading the maximum quality video and image content, please kindly hunt and find more enlightening video articles and graphics that fit your interests.

This Drive Pulley Always Turns. Videos you watch may be added to the TVs watch history and influence TV recommendations. If you know any 3 values Pulley sizes or RPM and need to calculate the 4th enter the 3 known values and hit Calculate to find the missing value. Double check all the pulleys on your deck and double check the belt. Tension and idler pulleys are an essential part of the auxiliary drive since they allow the belt to run efficiently even in the tightest of spaces.

Washer S Agitate Cycle Washing Machine Repair Samsung Washer Washing Machine From pinterest.com

Washer S Agitate Cycle Washing Machine Repair Samsung Washer Washing Machine From pinterest.com

Faster than pulley B. What this tells us is that the word sheave is probably a little older than pulley And sadly not much else. The armature plate and hub assembly are fastened to the compressor drive shaft. Lift system without an engine room which comprises a drive motor 2 a drive pulley 16 a lift cage 3 in cantilever mode of construction a counterweight 8 and vertical guide rails 5 10 which are arranged on one side of the lift cage for the lift cage and the counterweight wherein the drive motor 2 by way of the drive pulley 16 drives at least one flat-belt-like support andor drive means 12 which supports. Faster than pulleys A or C but not pulley B. In this video we work to get them back up and in good working condition.

If that spring is broke or missing that can cause the problem you have.

As a result Habasit generally recommends avoiding this combination. The armature plate and hub assembly are fastened to the compressor drive shaft. Remove the drive pulley. The drive pulley which is directly above the middle deck pulley turns and the spacer turns but the deck pulley doesntIm trying to find out what keeps the two pulleys spinning togetherIf there were no belt at all shouldnt they turn together if I. Tension and idler pulleys are an essential part of the auxiliary drive since they allow the belt to run efficiently even in the tightest of spaces. I noticed that the idler pulley PART NUMBER.

Source: pinterest.com

Source: pinterest.com

Turn cam to the desired position. Videos you watch may be added to the TVs watch history and influence TV recommendations. There is a rule in belt drive that states that the diameter ratio of the big pulley and small pulley should be 61 maximum. With the engine running and the brake off the drive belt is turning but the drive pulley PART NUMBER. Few examples are Lathe Machine Drill press milling machine etc.

Source: pinterest.com

Source: pinterest.com

To avoid this. A friction cover or rubber lagging helps to increase the traction between the conveyor belt and the drive pulley. The mower was running fine and just stopped. A round disk often with the grooves around the circumference. Remove the drive pulley.

Source: pinterest.com

Source: pinterest.com

If you look at the drive belt system and work the clutchbrake you will see a pulley and bracket that moves when you move the clutchbrake pedal. All drive pulleys must have two components. The center hub had melted out. Few examples are Lathe Machine Drill press milling machine etc. With the engine running and the brake off the drive belt is turning but the drive pulley PART NUMBER.

Source: motioncontroltips.com

Source: motioncontroltips.com

The magnetic coil does not turn since its magnetism is transmitted through the pulley to the armature. As a result Habasit generally recommends avoiding this combination. This is frequently accomplished with an attached hub which projects out from. 22 Using a breaker bar remove the drive pulley bolt and its conical spring washer. Zero turn and stupid pulleys.

Source: pinterest.com

Source: pinterest.com

The armature plate and hub assembly are fastened to the compressor drive shaft. Faster than pulley B. The armature plate and hub assembly are fastened to the compressor drive shaft. The drive pulley which is directly above the middle deck pulley turns and the spacer turns but the deck pulley doesntIm trying to find out what keeps the two pulleys spinning togetherIf there were no belt at all shouldnt they turn together if I. The belt will transfer the power to another pulley in the system.

Source:

Source:

There is a rule in belt drive that states that the diameter ratio of the big pulley and small pulley should be 61 maximum. In this video we work to get them. When its not driving the compressor the clutch pulley turns. As a result Habasit generally recommends avoiding this combination. The magnetic coil does not turn since its magnetism is transmitted through the pulley to the armature.

Source: phoenix-mfg.com

Source: phoenix-mfg.com

It doesnt even try to move when levers are pushed foward. When you change the belt to a different groove the corresponding other side also needs to be changed. Some underdrive pullies turn 30 less than other versions of this technology. A round disk often with the grooves around the circumference. Lift system without an engine room which comprises a drive motor 2 a drive pulley 16 a lift cage 3 in cantilever mode of construction a counterweight 8 and vertical guide rails 5 10 which are arranged on one side of the lift cage for the lift cage and the counterweight wherein the drive motor 2 by way of the drive pulley 16 drives at least one flat-belt-like support andor drive means 12 which supports.

Source: chegg.com

Source: chegg.com

That means you have less wear and tear happening on your sealed bearings and the bushings for your vehicle. It doesnt even try to move when levers are pushed foward. If you look at the drive belt system and work the clutchbrake you will see a pulley and bracket that moves when you move the clutchbrake pedal. Always the right belt tension. Lift system without an engine room which comprises a drive motor 2 a drive pulley 16 a lift cage 3 in cantilever mode of construction a counterweight 8 and vertical guide rails 5 10 which are arranged on one side of the lift cage for the lift cage and the counterweight wherein the drive motor 2 by way of the drive pulley 16 drives at least one flat-belt-like support andor drive means 12 which supports.

There is a rule in belt drive that states that the diameter ratio of the big pulley and small pulley should be 61 maximum. Drive pulley trouble on the Do-All saw never stops. Remove the drive pulley. So the pulley that drives the deck belt will always turn for as long as the engine runs. When properly engineered you can extend the life of your seats and races as well.

Source: pinterest.com

Source: pinterest.com

In this video we work to get them back up and in good working condition. Remove the drive pulley. Always the right belt tension. INA Tension and Idler Pulleys. The belt will transfer the power to another pulley in the system.

Source: pinterest.com

Source: pinterest.com

This is frequently accomplished with an attached hub which projects out from. There should be a spring that pulls that idler bracket back when you release the pedal. The center hub had melted out. The drive pulley which is directly above the middle deck pulley turns and the spacer turns but the deck pulley doesntIm trying to find out what keeps the two pulleys spinning togetherIf there were no belt at all shouldnt they turn together if I. If this ratio is more in any belt.

Source: pinterest.com

Source: pinterest.com

It doesnt even try to move when levers are pushed foward. Videos you watch may be added to the TVs watch history and influence TV recommendations. With the engine running and the brake off the drive belt is turning but the drive pulley PART NUMBER. A belt that is to short will always have to much tension and can. Stepped cone pulleys are always used in pairs.

Source: chegg.com

Source: chegg.com

INA Tension and Idler Pulleys. INA Tension and Idler Pulleys. Sheave it turns out can likely lay its origins at the feet of the proto-Germanic 500 BC word Scheibe which means diskUnfortunately another definition of sheave is bundle so we cant be totally certain about this one. If that spring is broke or missing that can cause the problem you have. The drive pulley which is directly above the middle deck pulley turns and the spacer turns but the deck pulley doesntIm trying to find out what keeps the two pulleys spinning togetherIf there were no belt at all shouldnt they turn together if I.

Source: pinterest.com

Source: pinterest.com

Faster than pulleys A or C but not pulley B. At the same time as pulley B and C. A round disk often with the grooves around the circumference. On the drive issue. If you know any 3 values Pulley sizes or RPM and need to calculate the 4th enter the 3 known values and hit Calculate to find the missing value.

Source: pinterest.com

Source: pinterest.com

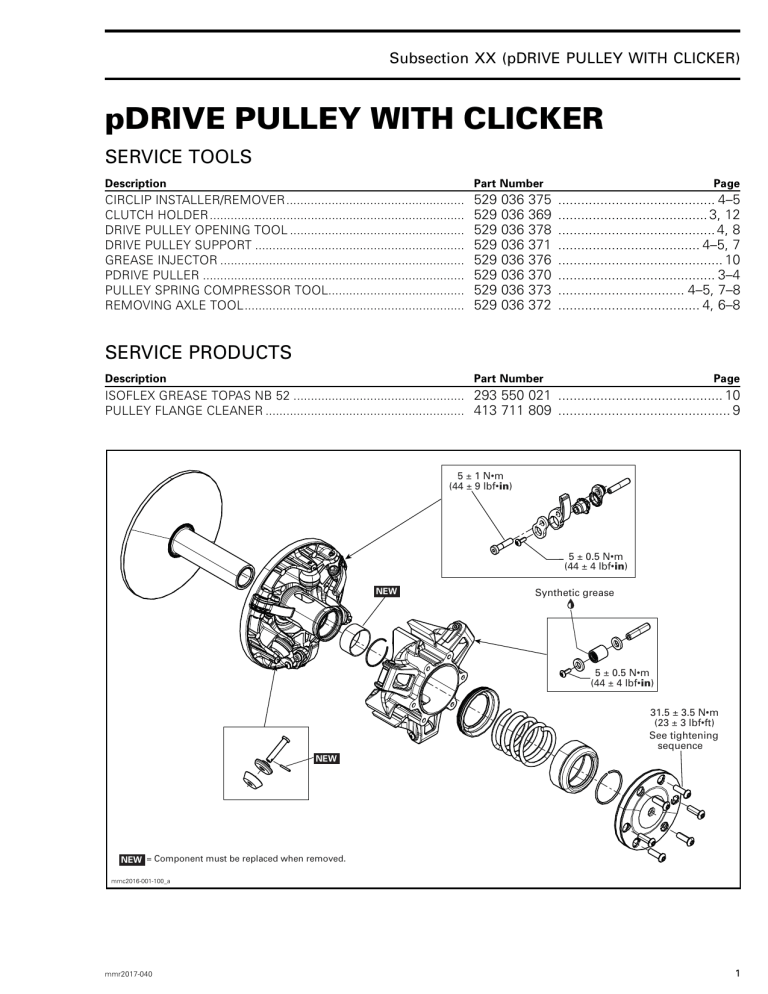

The magnetic coil does not turn since its magnetism is transmitted through the pulley to the armature. A friction cover or rubber lagging helps to increase the traction between the conveyor belt and the drive pulley. In this video we work to get them. NOTICE REQUIRED TOOLS CLUTCH HOLDER PN 420-660 PDRIVE PULLER PN 420-661 Subsection XX pDRIVE PULLEY WITH CLICKER mmr2017-040 5 1. The center hub had melted out.

Source: mathworks.com

Source: mathworks.com

In this video we work to get them back up and in good working condition. Videos you watch may be added to the TVs watch history and influence TV recommendations. I noticed that the idler pulley PART NUMBER. Electromagnetic coil flat springs pull the armature plate away from the pulley. Your accessory bearings for the alternator power steering pump and the air conditioning unit see the best results with this change.

Source: phoenix-mfg.com

Source: phoenix-mfg.com

22 Using a breaker bar remove the drive pulley bolt and its conical spring washer. Belt and both hydraulic pulleys are turning when engine runs. So drive is rotating the slowest B is fastest the other two in between. When you change the belt to a different groove the corresponding other side also needs to be changed. For example if your small pulley is 80mm diameter and spins at 1000 RPM and you need to find the second pulley size to spin it at 400 RPM Enter Pulley1 80 Pulley 1 RPM 1000 Pulley 2 RPM 400 and hit Calculate to find the second pulley diameter.

Source: chegg.com

Source: chegg.com

If you look at the drive belt system and work the clutchbrake you will see a pulley and bracket that moves when you move the clutchbrake pedal. My questions are should the drive pulley on top of the tranny turn. The magnetic coil does not turn since its magnetism is transmitted through the pulley to the armature. If playback doesnt begin shortly try restarting your device. 1401252 is pulled over so far that it butts up against the frame but the belt feels tight enough to turn the drive pulley if there isnt a great deal of friction from the transmission.

This site is an open community for users to do submittion their favorite wallpapers on the internet, all images or pictures in this website are for personal wallpaper use only, it is stricly prohibited to use this wallpaper for commercial purposes, if you are the author and find this image is shared without your permission, please kindly raise a DMCA report to Us.

If you find this site helpful, please support us by sharing this posts to your own social media accounts like Facebook, Instagram and so on or you can also bookmark this blog page with the title this drive pulley always turns by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.